There are many different rules for recycling different materials. Paper and cardboard go together, with plastic bottles in one bin, and glass in another, it is easy to get confused when it comes to recycling correctly. So how do you recycle rubber?

Rubber can be trashed or recycled. Recycling rubber requires devulcanization in order to break down the structure and bonds to allow for remodeling. Due to the complexity of this process, the general public should turn their used rubber into their local recycling company.

So why should rubber be recycled if it is such an arduous process? How is it completed and what are some other options? Read on to find out!

Why Recycle?

An estimated 230 million trashed tires could be found in landfills at the end of 2003. This large quantity of trashed rubber found in landfills only comes from tires, not accounting for a large amount of rubber from other trashed items. Since 2003 there has been a large boon in ways to dispose of these tires. Markets now dispose of around 80.4% of these tires in ways other than throwing them in a landfill.

According to the United States Environmental Protection Agency archive, these tires are recycled for these purposes in these percentages.

- 130 million (44.7%) are used as fuel

- 56 million (19.4%) are recycled or used in civil engineering projects

- 18 million (7.8%) are converted into ground rubber and recycled into products

- 12 million (4.3%) are converted into ground rubber and used in rubber-modified asphalt

- 9 million (3.1%) are exported to foreign countries to be reused as retreads

- 6.5 million (2.0 %) are recycled into cut/stamped/punched products

- 3 million (1.7%) are used in agricultural and miscellaneous uses

- 16.5 million scrapped tires are retreaded

Additionally, recycling rubber takes much less energy than it does to produce new rubber products. Recycling rubber tires can reduce your carbon footprint twenty times over due to the amount of carbon you avoid producing in the creation of four new tires.

Recycling rubber also keeps the rubber industry stable and avoids the need for expansion which could threaten tropical ecosystems or other locations where natural rubber is produced. Reducing demand for synthetic rubber also decreases the need for fossil fuels, which are used in the creation of synthetic rubber.

How to Recycle

Just like recycling or getting rid of large appliances or toxic waste, recycling rubber calls for assistance from professionals. The easiest way to recycle your rubber is to call or research your local recycling organization. There are different types of rubber and each is dealt with differently, make sure you research and know what type of rubber you have and ask the recyclers how they deal with each different piece of rubber you have. The recycling company will most likely have you drop off your rubber, separated by type, or will have a service come to pick up large quantities of rubber. Either way, this is your best option for getting the rubber off of your hands.

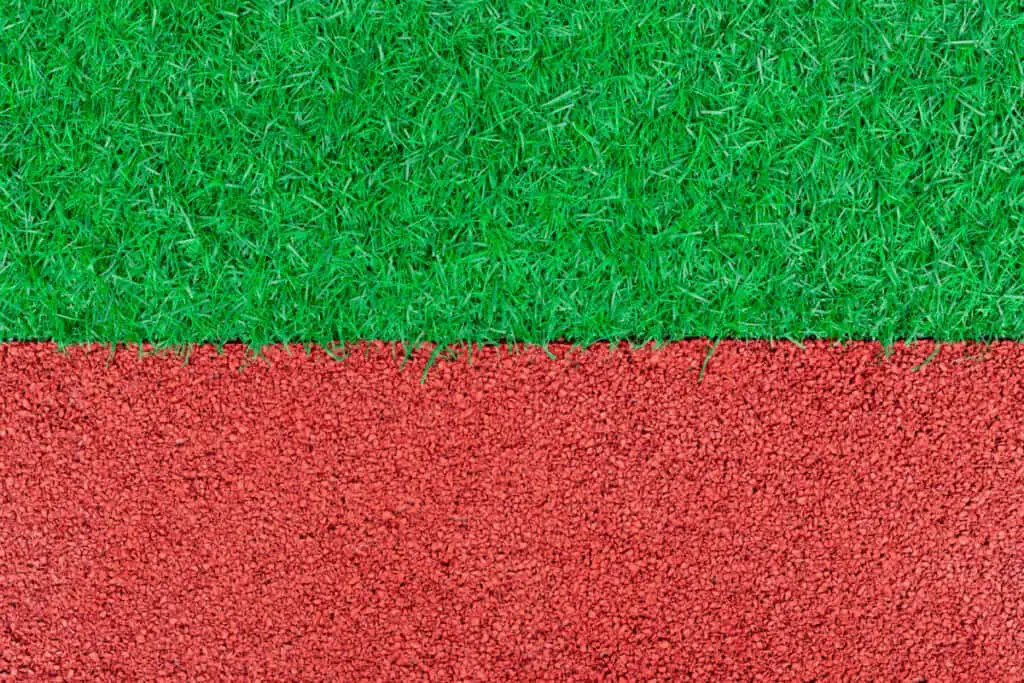

After the recycling company takes the rubber they will clean and break your rubber into more manageable pieces. After that, it will be put into a machine that turns it into even smaller pieces. This is called crumb rubber and is similar to turf used on fields. Unsurprisingly, this is one of the many uses of recycled rubber. It is often turned into the turf.

As mentioned before, rubber is chemically changed when made through a process called vulcanization. This is what makes the rubber more elastic. Devulcanizing the rubber makes it possible to remold and repurpose it without having to turn it into crumb rubber. This process calls for high heat and strong chemicals, which makes it a process only a professional company or organization can complete.

Uses of Recycled Rubber

There are many things that rubber can turn into after being recycled. One, as we mentioned before, is turf. Turf is used for football or soccer or many other sports fields. The rubber makes the artificial grass more bouncy like real grass. It can also be used for playgrounds. Using rubber for playground surfaces makes falling much less dangerous, and puts less strain on a child’s legs while jumping. You have likely seen rubber grounds, they look like squished together pieces of crumb rubber that have been melted together to create the ground. That is likely what they really are as well.

Recycled rubber can also be used to make the interior of cars, different types of mats for different purposes, they can be used for road repair, as well as turned into gardening tools or rubber protectors. Sometimes rubber is even used for shoes or other clothing items! This makes reusing rubber a very probable business that can produce many different products while helping the environment.

Refurbishing

Refurbishing your rubber is also a viable option for you. This is an interesting process and there are multiple versions of it. Some favor natural rubber and synthetic rubber is not often refurbished. These particular refurbishing processes are only used for relatively small pieces of natural rubber that have become dry, cracked, or lost elasticity. These methods mostly use chemicals you can find around your house and are perfect for rubber products that just need a bit more life.

Using ammonia and warm water you can submerge your rubber to restore your rubber’s softness. Submerge your rubber after cleaning it with a wire brush and making sure the water your clean with runs clear. Then leave the rubber in the ammonia water for a few hours, long enough for the ammonia to evaporate.

You can also use glycerine. Heating your rubber in hot water and then rubbing it down with glycerine will help to revitalize your rubber. Do this process multiple times for the best results.

Using lye water with 95% water and 5% lye will also work. After heating the lye to around 90 degrees, sink your rubber into the solution and leave it for ten days, replacing the lye every so often as it will dissolve. After ten days, wash your rubber with water and scrape any crusted parts of your rubber off.

Related Topics:

If you like the article above, here are some other similar articles you should check out!